11 Aug Renowned WSU wine scientist Tom Collins selected as inaugural Jackson Family Wines Endowed Professor

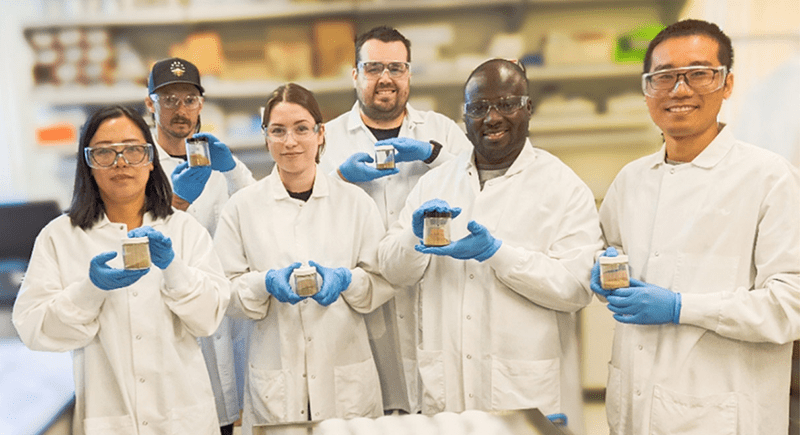

A longtime working relationship between Washington State University (WSU) scientist Tom Collins and Jackson Family Wines has evolved into the creation of an endowed professorship that recognizes Collins’ impactful wine science research and supports WSU’s Department of Viticulture & Enology (V&E)....