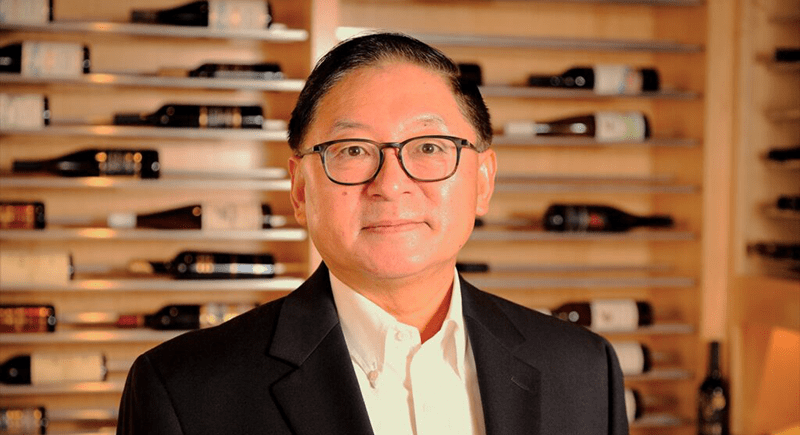

05 Dec WSU Tri-Cities INEF Director Noel Schulz elected to IEEE board

Washington State University Tri-Cities Institute for Northwest Energy Futures’ (INEF) Director Noel Schulz was recently elected to the Institute of Electrical and Electronics Engineers (IEEE) Board of Directors....