February 25, 2021 Professor developing way to turn sewage sludge into energy

RICHLAND, Wash. – A professor with the Bioproducts, Sciences and Engineering Laboratory at Washington State University Tri-Cities is developing a way to drastically improve energy production at small waste water treatment plants. The research has the potential to be scaled globally.

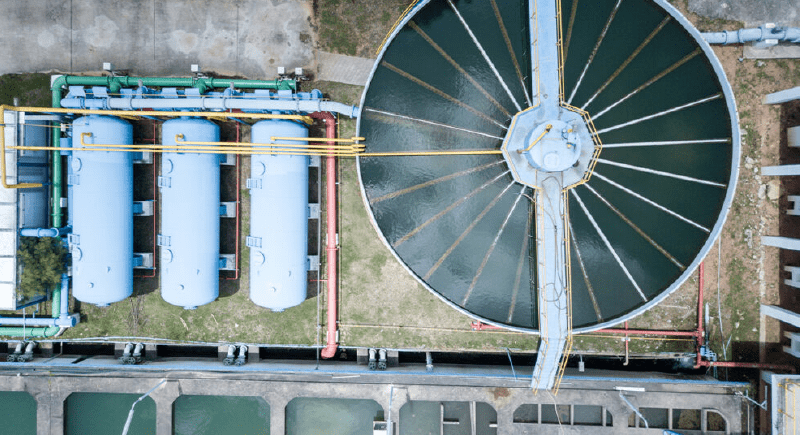

Pretreatment system used at the WSU bioproducts pilot plant.

Birgitte Ahring, professor of biological systems engineering and chemical engineering, received a $2.5 million grant from the U.S. Department of Energy Office of Energy Efficiency and Renewable Energy for the project. She is partnering locally with the Walla Walla Wastewater Treatment Plant, the Pacific Northwest National Laboratory and Clean-Vantage, LLC.

Sewage sludge is a remnant semi-solid material produced at sewage treatment plants. Ahring said while a portion of sludge is converted into biogas, at a mixture of 60% methane and 40% carbon dioxide at the majority of wastewater treatment facilities in the U.S., there still remains a significant portion of the waste to be disposed.

Ahring said converting a larger fraction of sewage sludge into useful energy will reduce the need for landfilling of the material and reduce the carbon footprint of wastewater treatment plants, worldwide.

New, more effective process

Ahring said many waste water treatment plants currently use a process called anaerobic digestion, which uses microorganisms that don’t require oxygen, to essentially digest some of the sludge material and to convert the organic material into biogas. Due to the nature of sewage sludge, part of the organic material will, however, be resistant to digestion using the process.

Birgitte Ahring, WSU professor of biological systems engineering and chemical engineering

Ahring said a much higher amount of biogas can be produced by applying a specialized upfront pretreatment process using heat and oxygen-based agents before the anaerobic digestion process. In a final process step, she said the biogas can be further upgraded to pure methane, which can be used as a bio-natural gas. Methane gas can be used by an assortment of transportation industries, and thereby as a substitution for diesel and gasoline as a renewable fuel.

Together, the integrated new process has been named the “Advanced Pretreatment/Anaerobic digestion technology.”

“Many of these plants, like the one in Walla Walla, produce biogas by anaerobic digestion, but the low efficiency means that the amount of biogas is too low for organized use of this fraction,” Ahring said. “What DOE was calling for was a rethinking of the way we process sewage sludge today, so that the process becomes far more efficient and economically viable.”

Currently, 40 to 50% of the carbon in sewage sludge is converted in the biogas process, Ahring said. With the new process, the team estimates they can improve carbon conversion efficiency by more than 50% from the current level. With the biogas upgrading, the overall methane yield is expected to increase by more than 100% compared to what is currently produced at wastewater treatment plants.

Upscaling the project for use globally

Ahring said once the new process has been demonstrated in pilot scale through a BSEL-based pilot facility, the process will be ready for upscaling at small plants, such as the Walla Walla Wastewater Treatment Plant. From there, the process will be ready to disseminate broadly in the U.S. and even globally, she said.

Ahring said partner Clean-Vantage, LLC, has worked on the specialized pretreatment for years, and has successfully licensed the process overseas for other applications. With the new technique for upgrading the biogas to pure methane being developed at WSU, the overall concept will enhance the potential for sewage sludge as a raw material for renewable energy production.

Ahring is working with colleagues at PNNL to produce the technical economics for upscaling and a disposal cost model, which will detail the actual cost of the project at wastewater treatment plants based on size. The model will also detail how many extra dollars will be profited with the additional energy production at wastewater treatment plants.

“With this project, we can show we can produce a high-value product while reducing the amount of sludge needing final disposal,” she said. “We are getting rid of a waste problem and turning it into a useable product. Other cities can then take this model and implement it in their own areas. I am confident we will make it work. All of us involved on the project have a lot of expertise in this area, and we have previous experience in working together.”

Media contacts:

- Birgitte Ahring, WSU Tri-Cities professor of biological systems engineering and chemical engineering, 509-372-7682, bka@wsu.edu

- Maegan Murray, WSU Tri-Cities director of marketing and communication, 619-403-3617 (cell), maegan_murray@wsu.edu