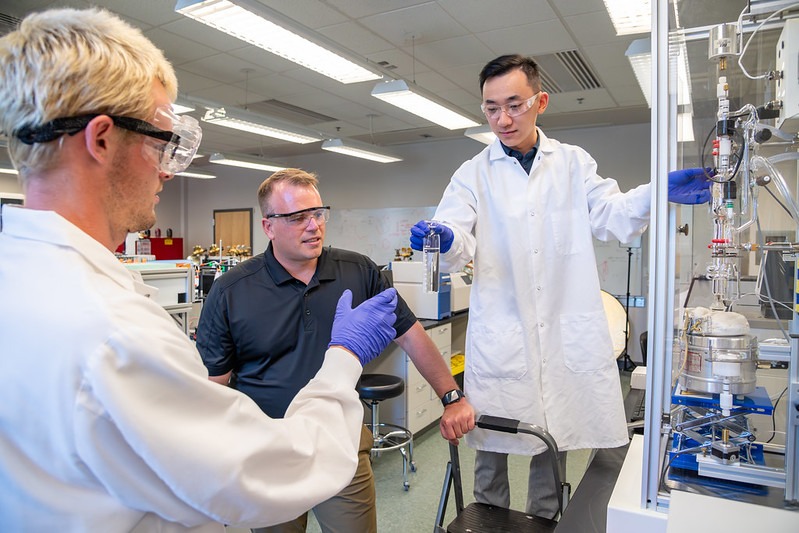

WSU Tri-Cities researcher helps put university at top of his field

A recent study published in the journal Heliyon found that WSU is globally the top contributing organization to scientific literature on the field of sustainable aviation fuel (SAF), based on an analysis of articles, papers, editorials, and news items published from 2001 to 2023....